Machines

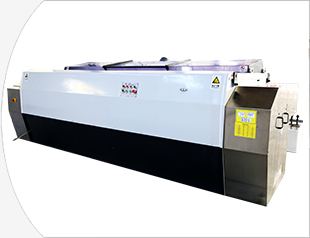

Etching Machine

HJ-SKJ etching machine is highly efficient corrosion equipment by fetching in advanced technique and equipment of developed countries. It adopts advanced microcomputer control, a high degree of automation, simple operation, reliable operation, convenient in operation and maintenance, advanced production technology.

HJ-SKJ etching machine is highly efficient corrosion equipment by fetching in advanced technique and equipment of developed countries. It adopts advanced microcomputer control, a high degree of automation, simple operation, reliable operation, convenient in operation and maintenance, advanced production technology.

Our company etching machine tub is only 1.3 meters high, especially easy for operation. Internal structure and the principle consistent with imported Germany corrosion machine. There are 6 rows of nozzles, including 4 row hydro jets, 2 row automatic water spray (equipped with manual hydraulic). The precision nozzle linearity ensures the fan in one plane. Electrical parts adopt PLC and touch screen control, ensuring safe and reliable use, simple and convenient operation, and high stability.

The filtering device uses the German technology, ensuring good filtering effect and no choking nozzle for a long time. Pipe with a German special device makes the formation of the etching liquid sector and sector contraction time very short, to ensure the uniformity of work piece corrosion, better corrosion effect and less waste fluid emission. Reclaiming tank liquid adopts frame structure at the bottom of the tub, ensuring flexible control. The liquid velocity is fast, only five seconds. Etching waste liquor is two liters, compared with the Germans, saving 20% to 30%.

FEATURES:

FEATURES:● Easy operation. Shrinkage time of sector forming is short.

● Fast back-flow velocity, good filtering effect

● Sector size, spray pattern, pressure are adjustable.

Product parameters:

● Dimensions: 4250×1950×1300

● Dimensions: 4250×1950×1300

● Weight: 3.5T

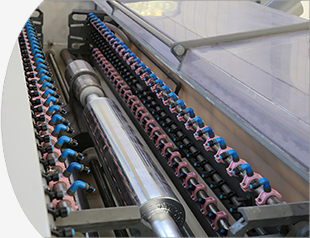

● Roller diameter: 500

● Jaw end distance: 2500

● Power: 2.5K

© Hongjian Gravure Systems 晋ICP备16001735号

Professional Manufacturer of Rotogravure Cylinder Making Equipment

Professional | Stable | Reliable

Professional | Stable | Reliable